Home > feeding equipment > Double body vibrating feeder

Product Introduction

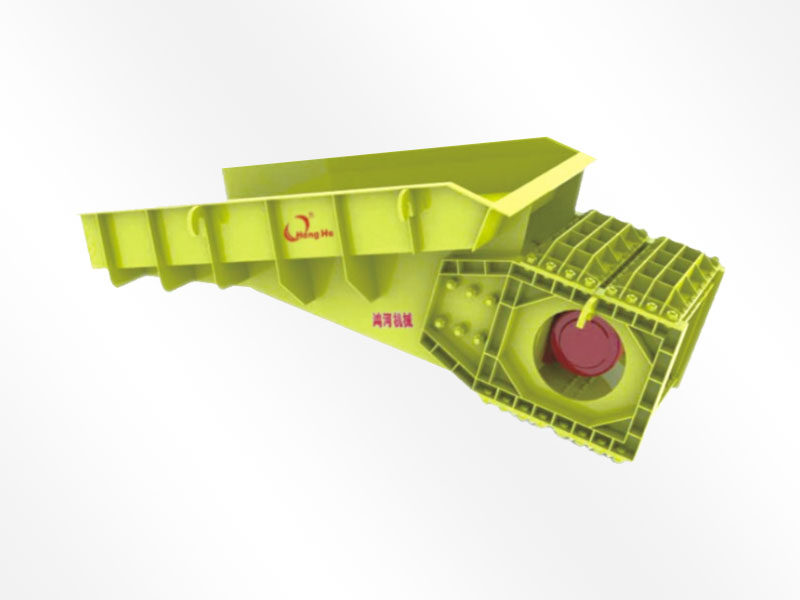

The dual mass vibrating feeder is the most advanced series of feeders developed by our company by absorbing advanced technology at home and abroad – the principle of dual mass resonance. Compared with the original domestic equipment, the XZG dual body resonant feeder has significant advantages, including reasonable design, compact structure, single vibration motor, stable start under balanced pressure, no influence of tank material load and jamming, labor-saving, noiseless, energy-saving, and large feeding capacity.

This model can meet the requirements of long-term continuous or intermittent operation during feeding

The machine requires low excitation force, minimal impact, smooth operation, stable amplitude, fast start-up, quick shutdown, and low maintenance workload.

The equipment has a compact structure and can achieve reasonable sealing. There is no leakage or spillage during feeding, and there is very little dust after sealing.

Ordinary, explosion-proof, 380V, 660V vibration motors can be selected to be matched with frequency converters for remote centralized control, facilitating modern management.

The dual mass vibrating feeder is the most advanced series of feeders developed by our company by absorbing advanced technology at home and abroad – the principle of dual mass resonance. Compared with the original domestic equipment, the XZG dual body resonant feeder has significant advantages, including reasonable design, compact structure, single vibration motor, stable start under balanced pressure, no influence of tank material load and jamming, labor-saving, noiseless, energy-saving, and large feeding capacity.

This type of dual body vibrating feeder has now developed into multiple specifications and varieties, with installation forms including suspended and seated. The feeding capacity can reach over 2000 tons/hour, and the feeding particle size can also reach 800-1000mm. It can be matched with a frequency converter to achieve variable frequency feeding, batching, and remote microcomputer operation control.

|

model |

Tank size |

productivity t/h |

Feed particle size |

Vibration frequency |

amplitude mm |

voltage V |

Power Kw |

||

| level | -10 | -12 | |||||||

|

XZGK1 |

200x600x100 |

5 |

10 |

15 |

50 |

1000 |

2 |

220-380 |

0.2 |

|

XZGK2 |

200x800x120 |

10 |

20 |

30 |

50 |

1000 |

2.5 |

220-380 |

0.2 |

|

XZGK3 |

400x900x150 |

20 |

50 |

80 |

70 |

1000 |

2.5 |

220-380 |

0.2 |

|

XZGK4 |

500x1100x200 |

50 |

100 |

150 |

100 |

1000 |

3 |

780-660 |

0.45 |

|

XZGK5 |

700x1200x250 |

100 |

150 |

200 |

150 |

1000 |

3 |

380-660 |

0.75 |

|

XZGK6 |

900x1600x250 |

150 |

250 |

350 |

200 |

1000 |

3.5 |

380-660 |

1.58 |

|

XZGK7 |

1100x1800x250 |

250 |

400 |

550 |

250 |

1000 |

3.5 |

380-660 |

2.4 |

|

XZGK8 |

1300x2200x300 |

400 |

600 |

800 |

300 |

1000 |

4 |

380-660 |

3.7 |

|

XZGK9 |

1500x2400x300 |

600 |

850 |

1000 |

350 |

1000 |

4 |

380-660 |

5.5 |

|

XZGK10 |

1800x2500x375 |

750 |

1100 |

1300 |

500 |

1000 |

5 |

380-660 |

7.5 |

|

XZGK11 |

2000x2800x375 |

1100 |

1500 |

1800 |

500 |

1000 |

5 |

380-660 |

10 |

Strict inspection before the product leaves the factory; Organize shipment according to the contract.

Assign dedicated after-sales service personnel to the site to provide guidance

Installation, debugging, and trial operation of guiding equipment;

Problems encountered by domestic customers during the production process, service

The staff guarantee to provide clear instructions within 24 hours

The solution is to rush to the site for processing as quickly as possible.

Adequate equipment spare parts and timely supply of spare parts enable Users can rest assured.

Provide customers with first-class equipment, technology, and services

Give clear solutions

Safe, high-quality, and reliable

Crafty manufacturing, striving for excellence

Email:

honghekj88@163.com