Home > Environmentally friendly vibrating screen > Environmental protection sieve

Product Introduction

Energy saving: The environmentally friendly screen adopts the advanced design concept of non vibrating screen box, which is more energy-efficient than traditional design schemes with the same screening area;

Environmentally friendly: Rigid connections are used at the feeding, discharging, and sieving funnel connections, achieving a sealed and static state. The box is tightly sealed, making it easy to form negative pressure for dust removal inside the sieve box, resulting in a more obvious dust removal effect and making the sieve machine more environmentally friendly and efficient, completely solving the requirements of on-site environmental protection;

1. The product should meet the standard requirements and be manufactured according to the approved drawings and documents according to the prescribed procedures.

2. Castings, forgings, and riveted welded parts shall comply with relevant standards and regulations.

3. The chemical composition and mechanical properties of raw materials should comply with relevant standards and regulations.

4. All outsourced and purchased parts must have a certificate of conformity and be inspected by the quality management department before assembly can proceed.

5. The product structure should ensure

.

6. Used on-site for easy maintenance and replacement of vulnerable parts;

7. Dust and oil leakage are not allowed to enter the exciter;

8. Bolts should be prevented from loosening;

9. Under normal working conditions, the product has no material deviation phenomenon.

Environmentally friendly strong screen is a screening equipment suitable for dry screening of wet fine-grained difficult to screen materials, and is currently the most effective screening equipment for handling wet materials. With the characteristics of large amplitude, high vibration intensity, and elastic screen surface, the strong screen is different from other types of screening equipment. It can effectively handle damp materials without clogging the sieve holes while ensuring processing capacity. During the work process, the maximum opening rate is always maintained, resulting in high screening efficiency, large processing capacity, replaceable screen plates, and reduced costs. The process parameters of strong screening with large amplitude, high vibration intensity, and elastic screening surface are used to improve the screening conditions of wet materials. The high vibration intensity and high speed of material movement enable fine-grained materials to quickly pass through the sieve, thereby minimizing the impact of moisture and viscosity on the screening effect. The super large screen surface and large processing capacity of the strong sieve can meet the production needs on site. The change in the mechanical structure of the sieve adopts a motion mode of multi-stage sieve surface vibration without the participation of the sieve box and frame in vibration, which solves the problem of large-scale screening equipment. The vibration intensity K value of the multi-stage screening surface is between 5 and 8, which is 2-3 times the vibration intensity of ordinary screening equipment. In order to achieve dynamic balance of the vibration system during motion, the adjacent screen surfaces of multiple sections produce relative motion of different phases, which largely offsets the inertial forces generated by the multiple screen surfaces during motion. During the operation of the screen surface, the screen box and frame have little impact on the foundation vibration. Strong screening is an effective screening equipment for processing high viscosity and humid materials

Screening systems for coal washing plants, solvent screening systems for steel enterprises, sand and gravel aggregate systems for the construction industry, metallurgical particle size grading, etc;

Sintering, blast furnace tank, coking, raw material plants, construction waste, sand and gravel aggregates, etc. in the metallurgical industry;

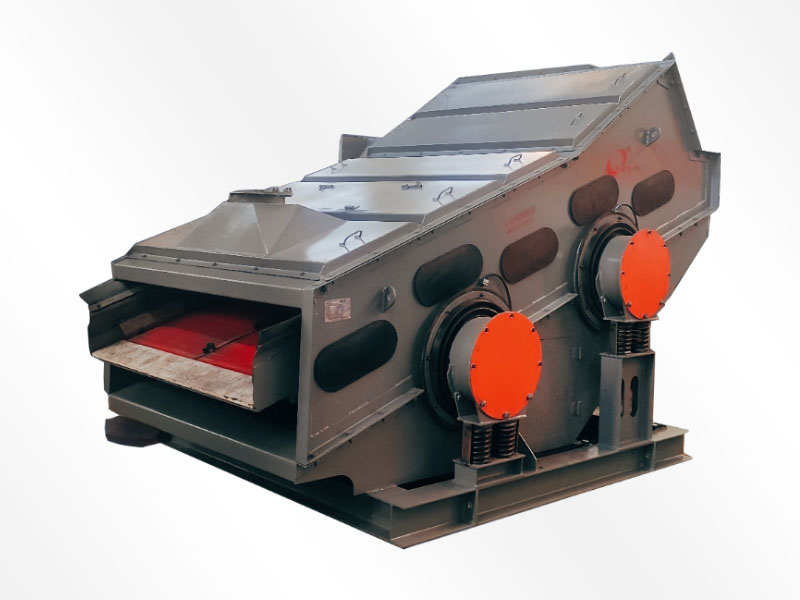

The environmentally friendly vibrating screen has changed the traditional mechanical structure of vibrating the screen surface and the screen box together. It adopts a motion mode of multiple independent screen surfaces vibrating while the screen box and frame do not vibrate. From the feeding port to the discharge end, the multiple screen surfaces vibrate independently, and the amplitude and vibration intensity of each screen surface can be adjusted. By adopting this structural approach, the vibration mass of the vibrating screen is reduced, making it easy to achieve large-scale motion parameters and screening equipment, meeting the screening process requirements and mechanical strength requirements for high vibration intensity. The structural form can adopt a circular vibration structure.

Composed of vibration source, screen body, sieve mesh, vibration reduction device, bottom support, and electrical control cabinet, etc;

Energy saving: The environmentally friendly screen adopts the advanced design concept of non vibrating screen box, which is more energy-efficient than traditional design schemes with the same screening area;

Environmentally friendly: Rigid connections are used at the feeding, discharging, and sieving funnel connections, achieving a sealed and static state. The box is tightly sealed, making it easy to form negative pressure for dust removal inside the sieve box, resulting in a more obvious dust removal effect and making the sieve machine more environmentally friendly and efficient, completely solving the requirements of on-site environmental protection;

Modularization: The screening machine is designed with a modular structure to ensure product quality and high interchangeability, and can achieve rapid delivery organized by the company;

Intelligence: The company adopts an intelligent control system to achieve online monitoring and fault diagnosis, centralized control of equipment and remote interlocking, online control through a mobile APP, and one click remote control operation, among other information collection technologies;

Muteness: The low noise effect of the screening equipment is reflected in the environmental screening, achieving the best results. The noise test is conducted at 62-72 decibels at a distance of 5 meters, which is the sound of two people talking;

Screening rate: By selecting process parameters such as large amplitude, high vibration intensity, and elastic screening surface, the screening conditions of the material can be improved. The high vibration intensity and high speed of material movement enable fine-grained materials to quickly pass through the sieve, with a screening efficiency of ≥ 85%;

Wear resistance: The structure design of the screen body adopts abrasive technology, and wear-resistant alloy steel coating protection is added to the worn parts of the main beam. The screen wire adopts high-strength 55CrSi rod or NM wear-resistant alloy steel, and the service life of the screen plate is ≥ 8 months;

Easy to maintain: Due to the use of screen mesh vibration, the screen box can be easily removed, making the screen mesh and exciter visually visible. They can be replaced as a whole or individually, making on-site maintenance easier and greatly reducing labor intensity and replacement time for workers. The sealing of chutes and chutes, chutes and sieve boxes, and hoppers and chutes all use quick release flexible joints, which do not require bolt fastening, making installation and disassembly convenient and reducing the workload of workers;

Basic investment: The design of the sieve box without vibration greatly reduces the vibration mass, reduces the foundation vibration force, reduces the static load, and reduces the dynamic load on the foundation. This reduces the demand for load during the design of the foundation structure, lowers the design and construction costs, and is particularly suitable for placing high-rise floor slabs;

Long life operation: The selection of new processes and materials is extremely strict, and the core components are made of German imported bearings and seals. In addition, the special structural design concept ensures the safe and stable operation of the whole machine, with a design life of more than 10 years;

The structure of the environmentally friendly strong screen mainly consists of a screen frame, screen box, screen plate, single and double group exciters, electric motors, damping springs, and other parts. Its characteristic is that the screen mesh is arranged horizontally with a single screen wire, and special structural design can also be carried out according to the customer’s on-site materials. The exciter is designed as a single and double group, and the trajectory of the screen vibration is circular or composite linear motion. The transmission adopts a tire type linkage motor for direct drag or an additional variable speed assembly for indirect drag.

(1) The deviation of vibration frequency per minute shall not exceed ± 2.5%;

(2) The amplitude difference of the symmetrical points on both sides of the screen box shall not exceed 1.5mm, and the lateral swing shall not exceed 1.5mm;

(3) Smooth, flexible, and unobstructed movement;

(4) The maximum temperature of the bearing shall not exceed 75 ℃, and the temperature rise shall not exceed 45 ℃;

(5) The no-load noise shall not exceed 78dB (A);

(6) The sieve plate should be firmly fixed on the main beam without any looseness;

(7) The springs used for each small sieve should be of equal height, with a maximum deviation of 5mm, and the stiffness difference between each spring should not exceed 5%.

(1) The blocking plate is made of cast 40Mn or NM400 special steel plate.

(2) There shall be no burrs around the cutting of steel plates and profiles.

(1) The exciter adopts German imported large clearance bearings and domestic first-line brands, with two structures of thin oil lubrication and molybdenum disulfide dry oil lubrication. The dry oil is designed for periodic automatic oil discharge.

(2) The parts of the exciter should not have cracks or other visible defects, and the rotating parts are not allowed to be welded or repaired.

(1) Apply anti rust oil to the exposed processing surface to prevent corrosion.

(2) The handwriting on the product label should be clear and neat, firmly fixed, and not skewed.

(3) The painting color should comply with the provisions of JB229-78 “Painting Colors and Safety Signs for Mining, Engineering, and Crane Transport Machinery Products”. The painted surface shall not have defects such as unevenness, cracks, peeling, bubbles, and marks.

(1) The overall part of the product;

(2) Electric motors and motor mounts;

(3) Supporting device;

(4) Spare parts provided according to the order contract.

(5) The product should have reliability and durability in use.

(6) If the product is damaged or cannot function properly due to poor manufacturing quality within 12 months from the date of delivery, provided that the user complies with the storage and use rules (excluding vulnerable parts), the manufacturer shall repair and replace the product free of charge for the user.

(1) The experiment should comply with relevant regulations.

(2) The amplitude symmetry point error is less than 1.5mm.

(3) The noise is measured using a precision sound level meter, set at a distance of 1 meter from the sound source, and the average value is taken from at least three measuring points on each side.

(4) The bearing temperature is measured using a point thermometer.

(1) The quality inspection department of the manufacturing plant shall only allow the products to leave the factory after passing the inspection.

(2) Factory acceptance tests should be conducted.

(3) The factory acceptance test shall be conducted at the manufacturing plant, and the continuous air transportation shall not be less than 8 hours.

(4) The basic parameters should comply with the provisions in the previous table;

(5) The product performance meets the requirements of Article 4.6;

(6) Provide a certificate of conformity and inspection report for the spring according to 4.9;

(7) The appearance of the product should be inspected for quality according to clauses 4.11, 4.12, and 4.13.

(1) Each product should have a product label fixed in a prominent position, with the following content on the label

a. Manufacturer name;

b. Product name and model;

c. Main parameters of the product;

d. Trademark;

e. Date of manufacture and factory number.

(2) The packaging of the vibrating screen should comply with the provisions of JB/ZQ4286

(3) Electric motors, springs, spare parts, vulnerable parts, tools, and random documents sent to users should be packed in boxes.

(4) The random files are first packed with plastic tape and placed in the box. The files include:

a. Packing list;

b. Product qualification certificate;

c. Product manual;

d. Installation diagram;

e. Other relevant technical materials

The transportation of products should comply with the relevant requirements and regulations of the country and transportation departments.

(1) The vibrating screen should be stored in a dry and clean place, placed steadily, at a certain distance from the ground, and not stacked.

(2) When placed outdoors, measures should be taken to prevent exposure to rain, sun, and water.

(3) The product should be maintained once a year after storage.

|

model |

Screen machine size m |

Screen surface |

Sieve size |

Vibration frequency r/mm |

amplitude mm |

Feed particle size mm |

Screening materials |

processing capacity t/n |

Motor power kw |

|

QLSF2042 |

2.0×4.2 |

25 |

18~40 |

960 |

5-9 |

0-100 |

limestone |

200~350 |

4*5.5 |

|

QLSF2042 |

2.0×4.2 |

25 |

4~10 |

960 |

5-9 |

0-100 |

lime |

50~200 |

4*5.5 |

|

QLSF2042 |

2.0×4.2 |

25 |

4~10 |

960 |

5-9 |

0-40 |

semi-coke |

50~150 |

4*5.5 |

|

QLSF2200 |

2.8×9.0 |

25 |

12~150 |

730 |

15~25 |

0-500 |

raw coal |

1000~2200 |

5*11 |

Strict inspection before the product leaves the factory; Organize shipment according to the contract.

Assign dedicated after-sales service personnel to the site to provide guidance

Installation, debugging, and trial operation of guiding equipment;

Problems encountered by domestic customers during the production process, service

The staff guarantee to provide clear instructions within 24 hours

The solution is to rush to the site for processing as quickly as possible.

Adequate equipment spare parts and timely supply of spare parts enable Users can rest assured.

Provide customers with first-class equipment, technology, and services

Give clear solutions

Safe, high-quality, and reliable

Crafty manufacturing, striving for excellence

Email:

honghekj88@163.com