Home > Linear vibrating screen > Linear dehydration sieve

Product Introduction

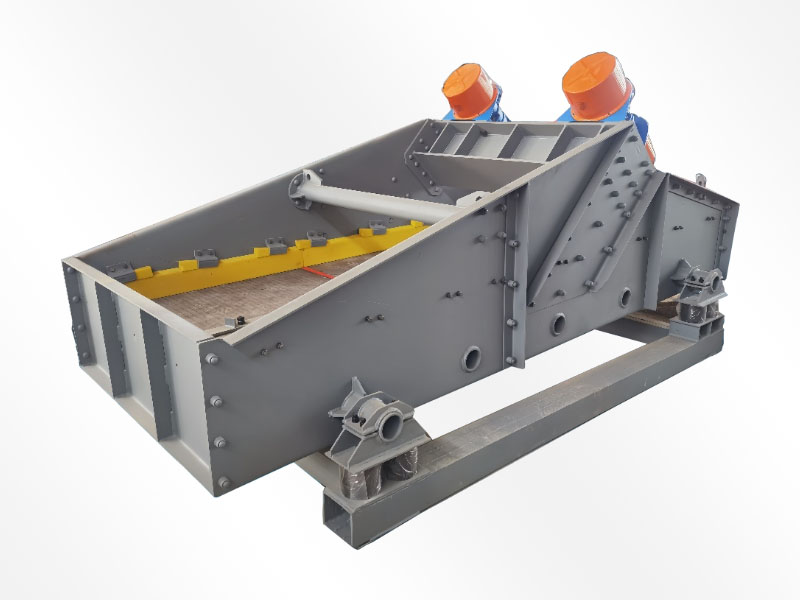

Dehydration screen, mainly used for dewatering, desliming, and desliming, can be used for washing sand in sand and gravel plants, recovering coal slurry in coal preparation plants, and dry discharge of tailings in mineral processing plants. Therefore, it is also called sand and gravel dewatering screen, mining dewatering screen, coal slurry dewatering screen, tailings dry discharge screen, high-frequency dewatering screen, etc.

Low noise and easy maintenance.

Reasonable structure, sturdy and durable.

Good dehydration effect, safe and reliable.

Large screening processing capacity and high screening efficiency.

5Lightweight, easy to disassemble and assemble, convenient for maintenance, and no sudden segment springs.

The dehydration screen adopts dual electrode self synchronization technology, universal eccentric block, and adjustable amplitude vibrator. It mainly consists of a screening box, exciter, support system, and motor. By using adhesive tape to drive two unrelated vibrators to operate synchronously and in reverse, the centrifugal force generated by the two sets of eccentric masses along the vibration direction is superimposed, and the reverse centrifugal force cancels out, thus forming a single excitation vibration along the vibration direction, causing the sieve box to move back and forth in a straight line.

1. The vibration motor of the dehydration screen [1] is easy to replace, and the rubber spring on the base is used for shock absorption, so that the amplitude is small and the vibration is slow, and it can be completely removed.

2. It can be customized according to production capacity and moisture content. The side panels of the body have reinforced plates, the bottom is equipped with supports, and there are horizontal bars at the bottom. The discharge port is supported by triangular steel plates, which are thick,

3. The vibration motor is fixed with high-strength bolts, and the bottom spring is a rubber spring. The quality of the spring will affect the service life of the vibration motor. The fixed density of the sieve plate is high, and there are reinforcing ribs in the sieve plate,

4. After welding, the welder must strictly avoid welding holes and support the bottom with channel steel.

5. In addition, the sieve holes can be adjusted as needed, resulting in low equipment noise and good dehydration effect.

6. Before shipment, the staff will debug it to ensure that the vibration motor is functioning properly and the exciter is operating properly, in order to guarantee the quality of the factory products for customers.

7. The added value of dewatering screen: For products with low mud content, dewatering screen can also be directly used without the need for sand washing machine, which saves customers’ costs and achieves the same effect.

Indicate the mesh structure (preparation, punching, seam), mesh size, processing capacity, and material particle size.

The most important branch of the dehydration screen family is the high-frequency dehydration screen. The high-frequency dehydration screen is a type of screen that uses its own multiple frequencies for dehydration, and is the latest type of dehydration screen. It is energy-saving, environmentally friendly, low-carbon and green, and meets the requirements of building a sustainable society. The high-frequency dewatering screen is mainly used in processes such as tailings dry discharge, and its effect is extremely obvious. It is a landmark equipment for the new generation of tailings dry discharge.

After the trial operation is completed, check that the above content is correct, re tighten all fasteners, and ensure that the screen mesh and all components are securely fastened before formal use. Prior to this, the following tasks must be completed:

1) The training of operators should understand the various structures and simple working principles of the equipment; Before starting work, it is necessary to prepare for driving, check that the rotating parts are flexible and unobstructed, the screen mesh is intact, all components are not loose, and the bolts are tightened.

2) The no-load start and stop vibrating screen is generally used in crushing and screening equipment or washing processes, requiring the screen machine to start and stop without load. Therefore, it is necessary to follow the principle of starting the reverse process flow and stopping the process flow. Except for special reasons, parking with materials is not allowed. When there is material accumulation on the screen surface, it must be removed before starting. Only after normal operation can feeding begin.

Strict inspection before the product leaves the factory; Organize shipment according to the contract.

Assign dedicated after-sales service personnel to the site to provide guidance

Installation, debugging, and trial operation of guiding equipment;

Problems encountered by domestic customers during the production process, service

The staff guarantee to provide clear instructions within 24 hours

The solution is to rush to the site for processing as quickly as possible.

Adequate equipment spare parts and timely supply of spare parts enable Users can rest assured.

Provide customers with first-class equipment, technology, and services

Give clear solutions

Safe, high-quality, and reliable

Crafty manufacturing, striving for excellence

Email:

honghekj88@163.com